Particle Cleaning Solution Expert

You don’t need to specialize in cleaning technology to produce high-cleanliness products.

Eco-lander integrates cleaning machine makers, chemical specialists, and inspection professionals into one, offering high-quality, efficient, environmentally safe, and sustainable solutions for you.

High-cleanliness solutions originating from Germany

We focus on partnering with you to provide efficient and eco-friendly solutions in industries such as semiconductor equipment components, AI server cooling systems, medical devices, aerospace, automotive, and electronic assembly, ensuring your products meet the highest cleanliness standards.

Successful Stories

Service Process

1. Cleaning Requirement Planning with Customers

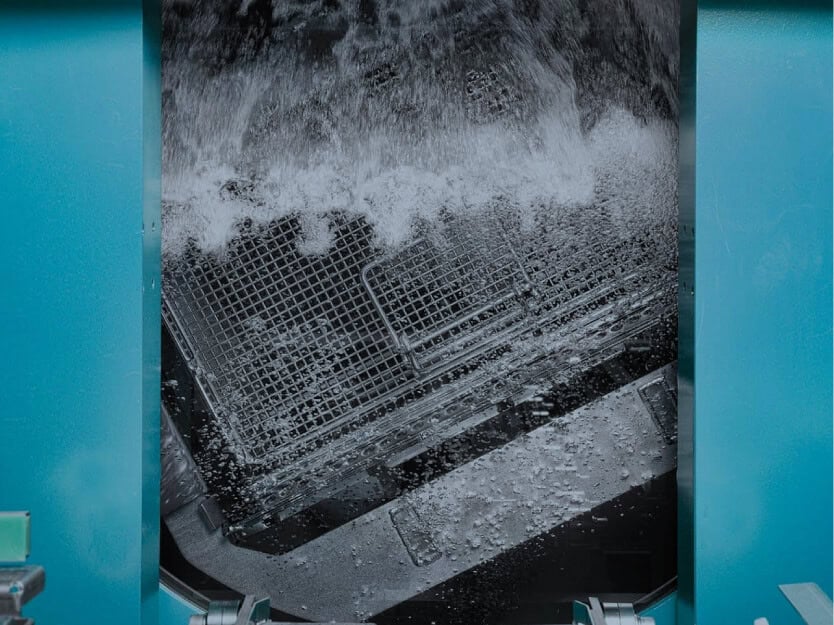

2. Trial Cleaning at our Technical Center

3. Evaluating Mass Production Solutions

4. Contract Signing & Solution Preparation

5. Solution Execution & Ongoing Support

Knowledge

With the rapid development of artificial intelligence (AI) technology, the demand for high-performance servers is increasing. Traditional air-cooled cooling methods have been unable to meet the heat dissipation needs of high-density computing environments, making liquid cooling technology a key solution for data centers and edge computing facilities. Among the many liquid cooling media, PG 25 (Propylene Glycol 25%) coolant is widely used in closed-loop cooling systems due to its excellent thermal conductivity and system compatibility.

Frequency declining of ultrasonic rods (transducers) in vacuum closed cleaning equipment is a critical issue that directly affects cleaning effectiveness. Due to the vacuum closed system, direct internal measurement can be difficult, but there are still some methods to indirectly or directly detect it:

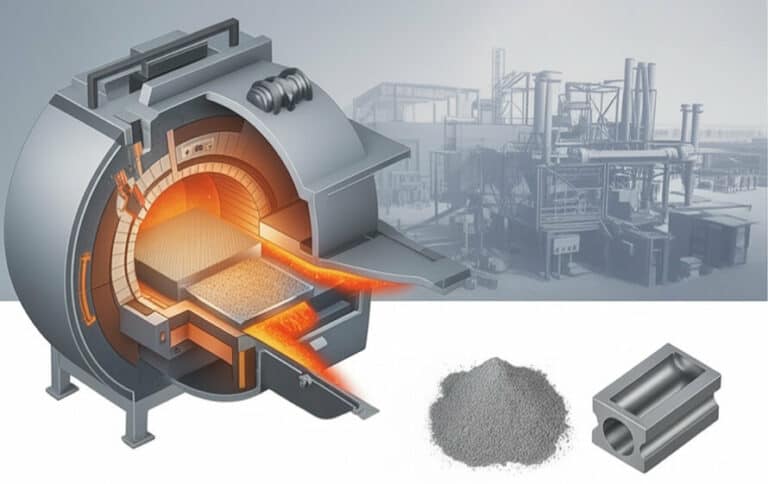

Previously, component cleaning focused on removing surface particles, but future challenges will increasingly involve oil film or grease-form contamination becoming the primary focus. Current major automotive industry trends, including Industry 4.0, electric vehicles, and autonomous driving, significantly impact component cleaning. While removing particles and chips from processed components remains important, we must introduce new requirements and techniques while ensuring component cleanliness. Traditional production lines manufacturing nearly identical components with short cycles are being replaced by more flexible, less human-intervention automated modes involving broader cleaning tasks.

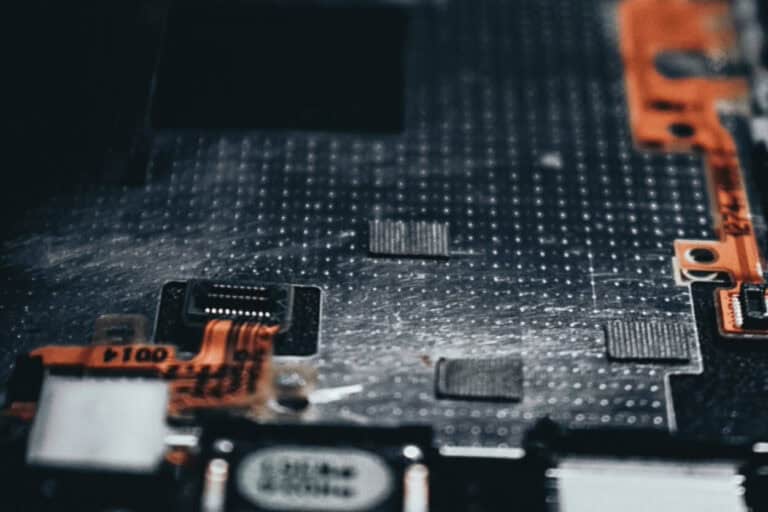

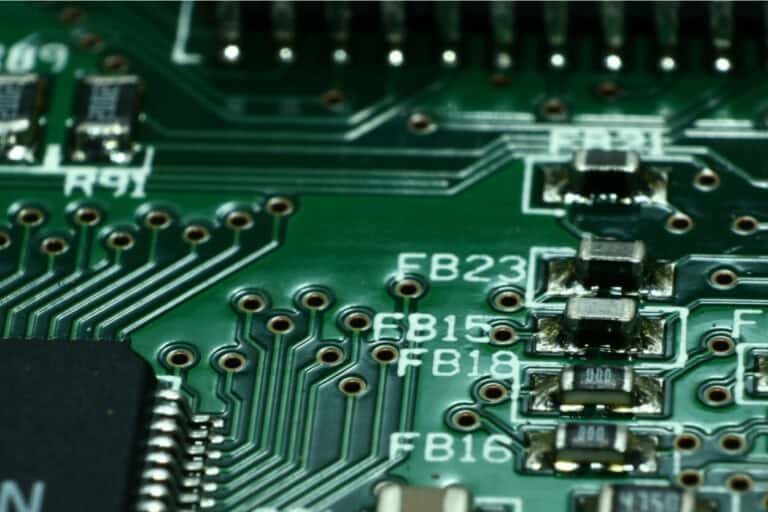

According to literature, two different methods can be used to achieve technical cleanliness for electronic components or parts, particularly for high-pressure components. Particles that may occur during assembly and manufacturing can be referenced in the VDA 19.2 assembly environment particle cleanliness course content.

Current major automotive industry trends, including Industry 4.0, electric vehicles, and autonomous driving, significantly impact component cleaning. Previously, component cleaning focused on surface particle removal, but future challenges will increasingly involve oil film or grease-form contamination.