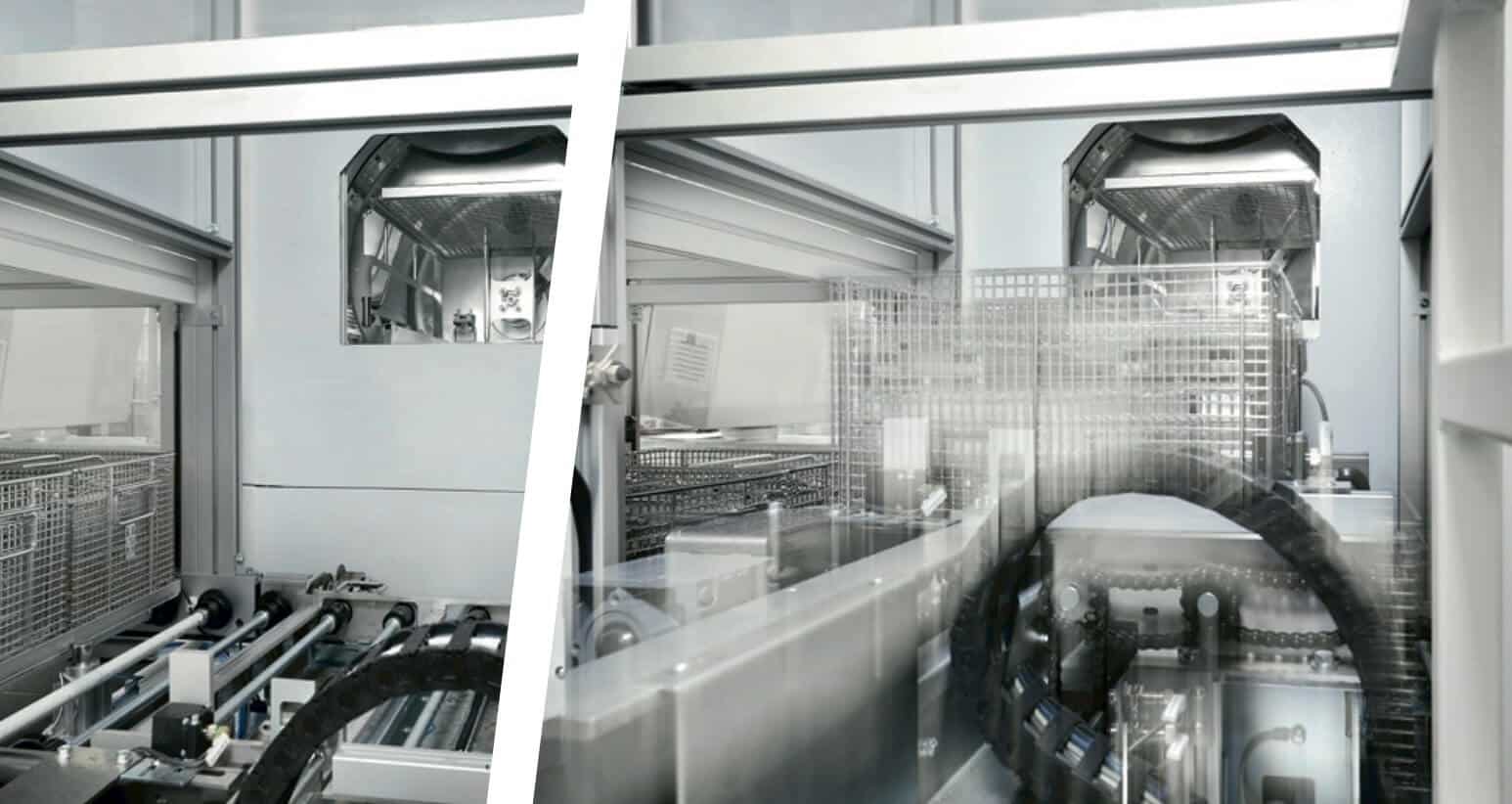

In the cleanroom production areas of TRUMPF Laser SE in Schramberg, strict cleanliness requirements apply. The MAFAC PALMA ensures the necessary particle and film cleanliness of laser components to maintain their full functionality. Particularly, laser-guiding components must be entirely residue-free to guarantee precise performance.

Challenges:

- Cleaning a wide variety of components (ranging from 1 mm to 500 x 300 x 250 mm) made of materials such as aluminum, stainless steel, copper, and plastics.

- Removing contaminants from deep, hard-to-reach holes and complex geometries.

- Preventing particle transfer and recontamination in sensitive assembly areas.

- Ensuring contamination-free transfer into the cleanroom.

Solution: The MAFAC PALMA employs a multi-stage cleaning process that combines spray flooding, ultrasonic cleaning, vacuum technology, and kinematic cleaning. Multiple rinsing stages with specially treated water prevent recontamination. The final drying process involves pulsed high-purity compressed air, hot air, and vacuum drying.

Want to know more?

Let’s go to download page to learn the whole successful story!