From Surface Particles to Oil Films and Grease, Automotive Component Cleaning Trends

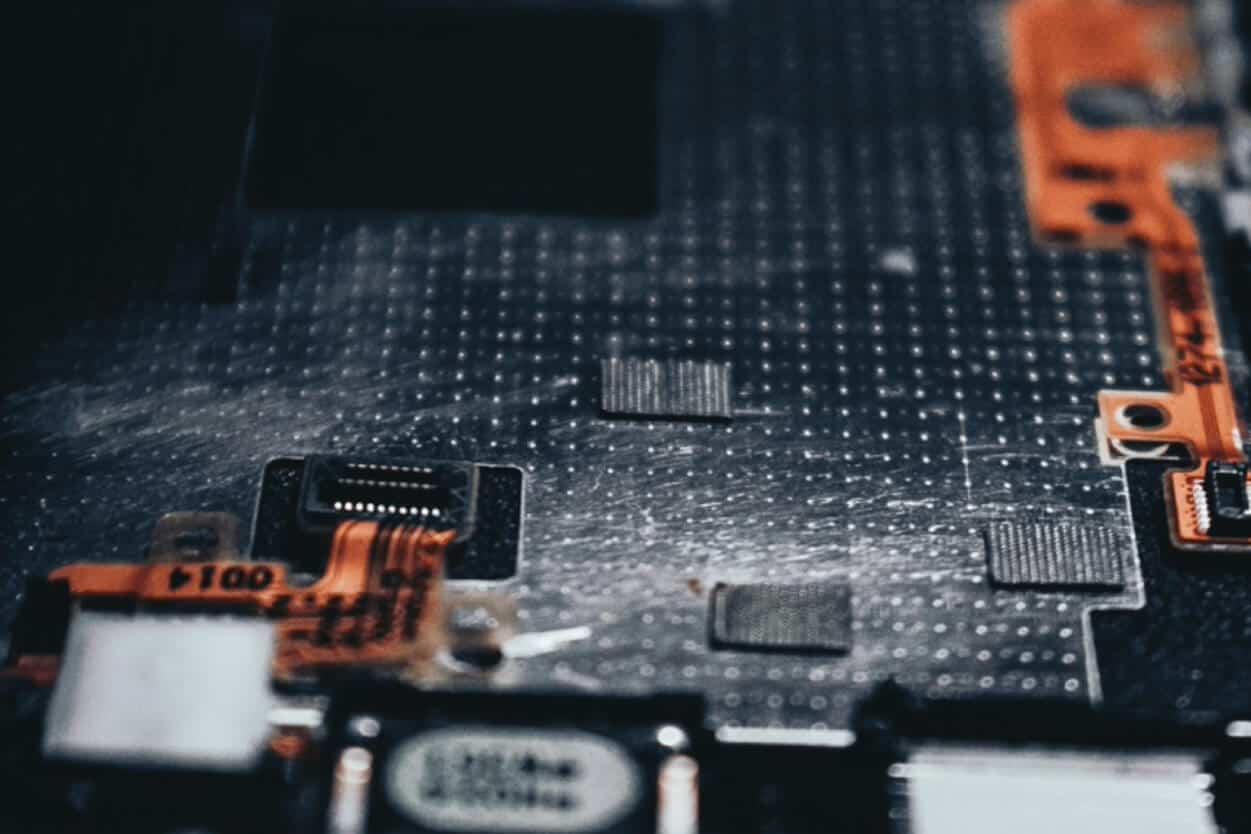

Previously, component cleaning focused on removing surface particles, but future challenges will increasingly involve oil film or grease-form contamination becoming the primary focus. Current major automotive industry trends, including Industry 4.0, electric vehicles, and autonomous driving, significantly impact component cleaning. While removing particles and chips from processed components remains important, we must introduce new requirements and techniques while ensuring component cleanliness. Traditional production lines manufacturing nearly identical components with short cycles are being replaced by more flexible, less human-intervention automated modes involving broader cleaning tasks.

📍 Extended Reading:

Particle Cleanliness Inspection Conforming to ISO 16232, VDA 19! Best Cleanliness Solution

Discussing the Importance of Cleanliness for Electric Vehicle Components in German Cars like BMW and VW!

The Rise of Automotive Autonomous Driving Increases Internal Precision Component Cleanliness Standards

Increasingly sophisticated engine designs and transmission developments are driving demand for cleaning machines meeting specific particle cleanliness standards. Additionally, new materials like lightweight metals are continuously being introduced and improved across various processing techniques. The rise of autonomous driving will change component cleanliness standards, as it requires elevated internal precision component supply cleanliness to ensure smooth engine component operation and provide drivers with safer driving guarantees! Current autonomous driving assistance systems feature numerous optical sensors, especially involving multiple precise cleaning stages in automotive industry supplier production processes. Autonomous driving implementation will demand high vehicle safety with comprehensive automotive safety system equipment. Components and elements must meet the highest standards for particles and especially contamination films. Moreover, production processes must be completely traceable and auditable.

#Extremely Clean Washing Equipment #Wet Cleaning

Removing film contamination, cleaning capillary structures, and preparing surfaces for welding, coating, and bonding will require increasingly complex processes. We must be able to utilize appropriate chemicals, suitable cleaning methods, and customized drying functions for each component type, documenting every process stage. Past cleaning models will face significant challenges. For precision component cleanliness, reference can be made to the German Automotive Industry Association standards VDA 19.1 and VDA 19.2 Assembly Environment Technical Cleanliness regulations, as well as ISO 16232 applicable to American car manufacturers.

Welcome to contact Eco-lander to learn about dry and liquid solvent cleaning recommendations and services for electronic components!

📍 Director Hong sarah@eco-lander.com