What are VW 01134 and BMW QV11111? All EV component cleanliness standards stem from German automotive industry benchmarks.

When it comes to cleanliness standards for German cars, the German Automotive Industry Association (VDA) must be mentioned. The VDA comprises over 600 member companies, including German automakers and suppliers, dedicated to researching and producing cleaner, safer road vehicles. According to the sixth edition of the VDA PPA (Production Process and Product Approval) in 2020, Technical Cleanliness has been officially included as a standard requirement. Automaker clients typically evaluate suppliers through RFQ (Request for Quotation) drawings, SSA (Supplier Self-Assessment), and VDA 6.3 P1 scoring to determine qualification. Once approved, suppliers receive orders and undergo rigorous, unannounced technical audits (TRL) to ensure the VDA supply chain achieves impeccable quality. VDA certification represents the highest principle of trust automakers place in their suppliers!

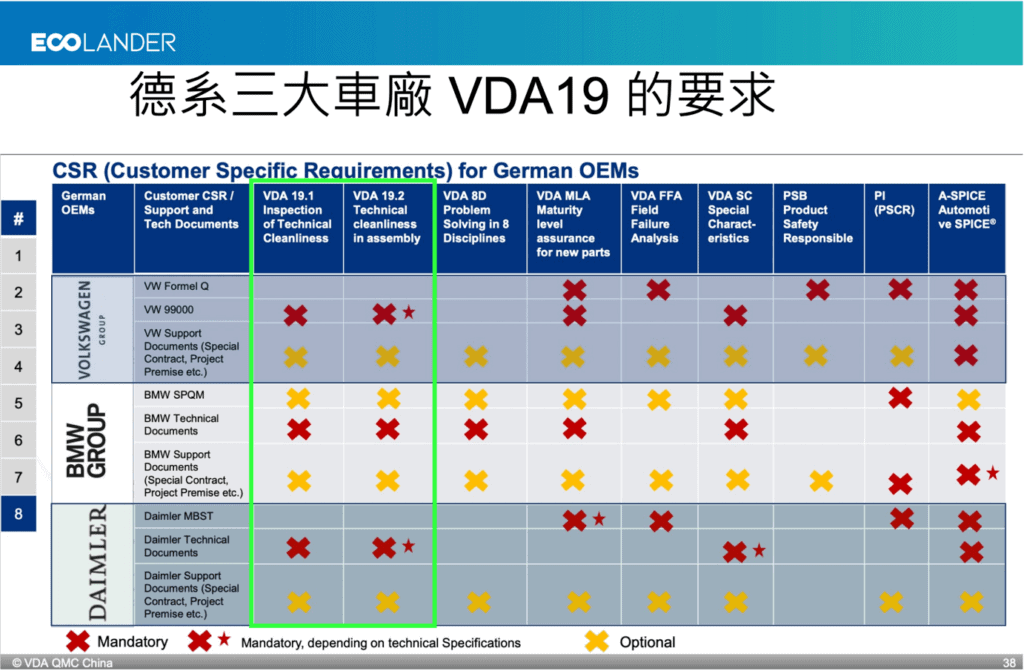

Consequently, major automakers like the Volkswagen Group (including Porsche and Audi), BMW Group, and Mercedes-Benz (including Daimler Truck) mandate that their Tier 1 system suppliers, as well as Tier 2 and Tier 3 suppliers, provide components meeting cleanliness standards (e.g., VW 01134, BMW QV11111, and other VDA 19 requirements—see table below for details).

Why Is Component Cleanliness Critical for EVs and the Automotive Industry?

📍Learn More About Professional Cleaning Technology: Chemical Solvent Analysis & Inspection