Industry

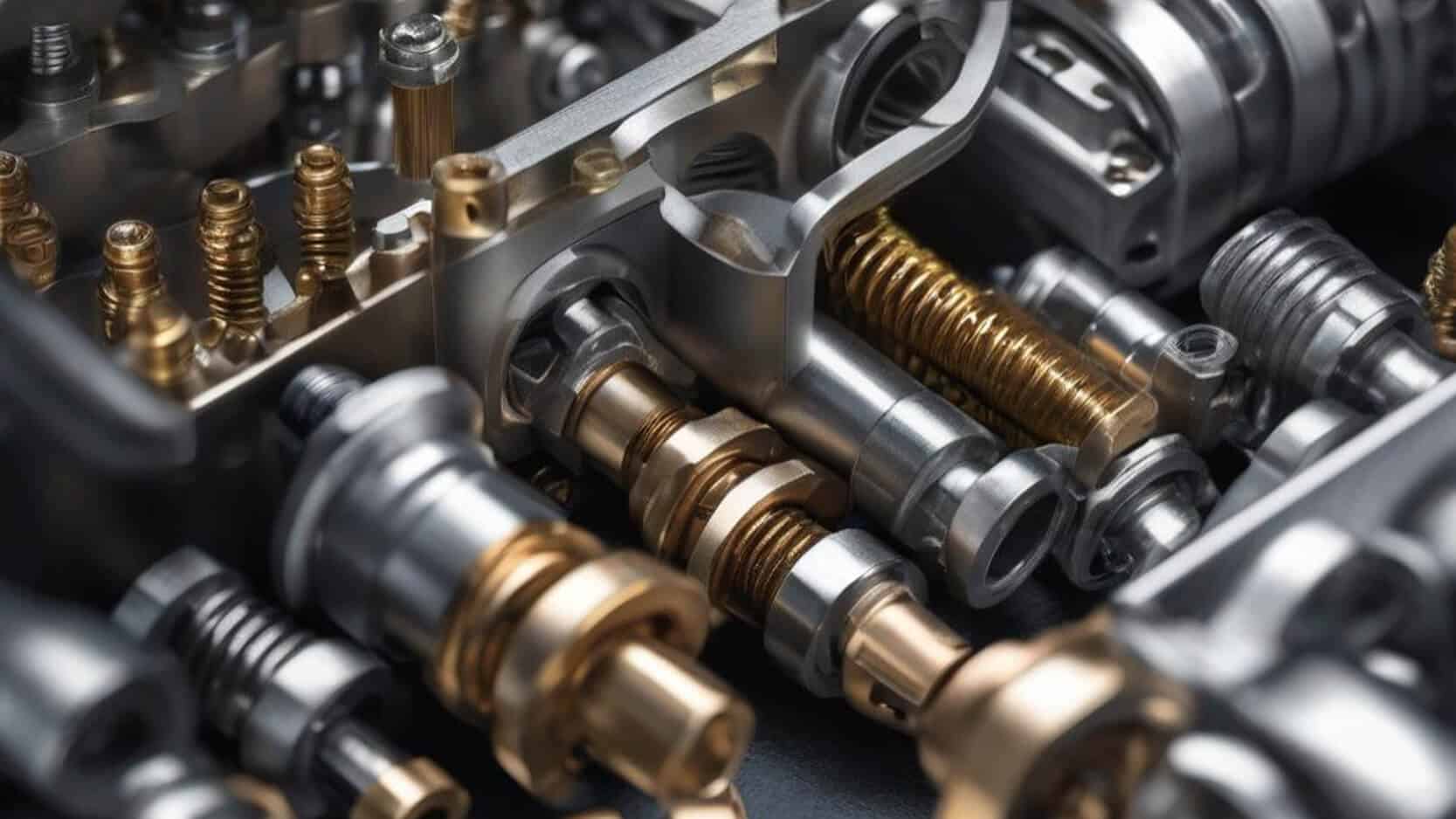

Precision Fastener

Why High-Purity needed

The cleanliness standards for precision fasteners follow international standards such as VDA19 and ISO16232

Precision fasteners, such as screws, nuts, and washers, are essential in high-precision applications and require strict cleanliness standards for several reasons:

- Increase Reliability: Particle contamination can cause fasteners to loosen or not tighten properly, negatively impacting system stability and increasing the risk of failure, particularly in high-pressure and high-vibration environments.

- Ensure Assembly Precision: Contaminants can affect the dimensional accuracy and surface finish of fasteners, leading to gaps or misalignment during assembly, which compromises overall precision.

- Extend Service Life: Contaminants can accelerate wear and corrosion, shortening the service life of fasteners. Maintaining high cleanliness levels reduces maintenance and replacement frequency, effectively lowering operational costs.

- Improve Function and Performance: In high-precision applications, contamination can hinder the motion performance and functionality of fasteners, affecting the overall stability and efficiency of equipment operation.

Ensuring high cleanliness standards for precision fasteners is crucial for maximizing reliability, performance, and cost-effectiveness in your applications.

Industry Cleanliness Standard

Precision fasteners adhere to international cleanliness standards such as VDA 19 and ISO 16232

Typically, the cleanliness requirement mandates the absence of particles larger than 600µm or 400µm. For specialized applications, including semiconductor equipment and aerospace industries, even stricter limits on the number and size of metal particles are imposed to meet the demands of high-precision operations.

Our Solutions

Full Vacuum Close System Cleaning Machines

- Customized Cleaning Processes: We adjust the cleaning method, temperature, and duration based on material and surface treatments (such as electroplating and anodizing) to achieve optimal results.

- Effective Cleaning through Physical and Chemical Forces: Utilizing ultrasonic waves, spray, steam and bubble forces combined with eco-friendly solvents or aqueous-based cleaning agents, we effectively remove oil, particles, and trace contaminants.

- Three-Stage Filtration Circuits: Our high-efficiency filtration systems ensure that each fastener is thoroughly cleaned, meeting rigorous precision cleanliness standards.

- Eco-Friendly Cleaning and Efficient Drying: We use environmentally friendly solvents that effectively remove oil, and our high-efficiency drying system guarantees fasteners are free from liquid residue or contaminants.

- Integrated Automation: Our scalable and automated feeding system ensures efficient workflow integration with upstream and downstream processes.

- TAF Approved Particle Inspection: Post-cleaning particle inspection ensures that we deliver the highest quality results.

Choose our advanced cleaning solutions to enhance the reliability and performance of your precision fasteners.