Industry

Fuel Vehicle / Electric Vehicle Components

Why High-Purity needed

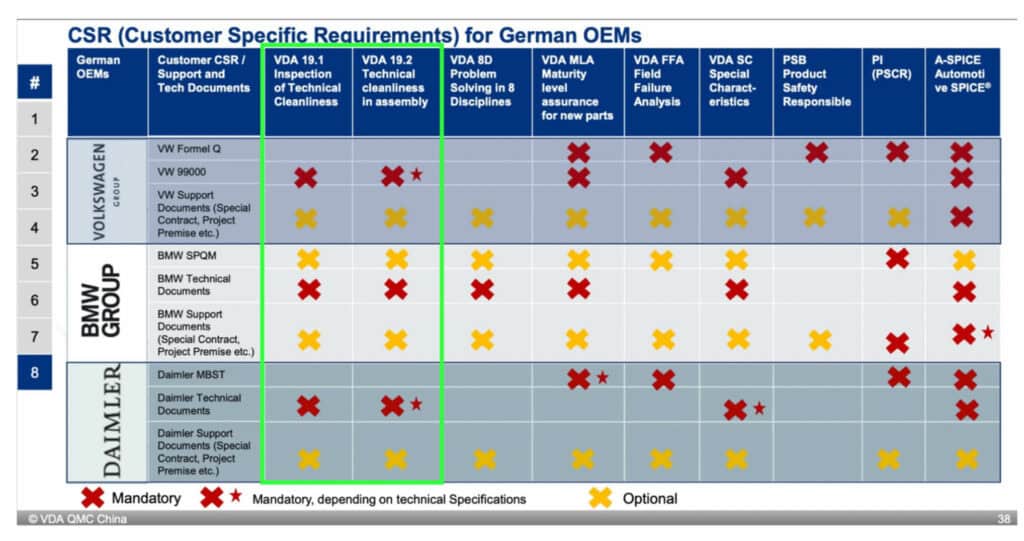

Suppliers should meet VDA Certification Standards

- The German Automotive Industry Association (VDA) mandates technical cleanliness through VDA PPA 2020 (6th Edition).

- VDA 19.1 and VDA 19.2 regulations apply to Tier 1, Tier 2, and Tier 3 suppliers, ensuring compliance with standards set by VW, BMW, and Mercedes-Benz.

- Automakers conduct unannounced Technical Readiness Level (TRL) audits to verify adherence to cleanliness requirements.

Contamination Risks

- Particle Contamination:

- Operational Issues: Contaminants can affect bearings, valve bodies, and fuel injectors, reducing precision.

- Dimensional Tolerances: Microscopic contaminants may cause deviations in tolerances.

- Electronic Short Circuits: Metallic particles can lead to short circuits in electronic control units (ECUs).

- Reduced Component Lifespan: Inadequate cleanliness accelerates material degradation and corrosion

The German Big Three automakers—Volkswagen Group (including Porsche and Audi), Mercedes-Benz, Daimler Truck, and BMW Group—require compliance with VDA 19.1 and VDA 19.2 cleanliness standards throughout their supply chains. Adhering to these high cleanliness standards is essential for ensuring the reliability and performance of components in your vehicles.

Industry Cleanliness Standard

Each major automotive system has strict cleanliness limits for critical components

- Fuel Lines / ABS / Injection Systems— Maximum 100-300μm metal particles.

- Hydraulic Systems— Maximum 150-600μm metal particles.

- Transmission Systems— Maximum 300-700μm metal particles.

Our Solutions

Full Vacuum Close System Cleaning Technology

- Ultrasonic, Steam, Spray, dripping and multiple cleaning process: Utilizes high-purity solvents for effective cleaning.

- Vacuum Drying Technology: Ensures spot-free drying for your components.

- Integrated automation: Scalable and automized feeding for efficient workflow integrated with the up and downstream process.

- Compatibility: Suitable for various automotive component materials.

Quality Assurance and Particle Inspection

- Compliant with VDA 19 and ISO 16232 international standards.

- TAF-Certified Particle Testing Laboratory.

- VDA 19.1 Certified Extraction Equipment.

- Advanced Scanning Electron Microscope (SEM) and Laser Particle Size Analyzer.

- Comprehensive particle analysis reports provided.

Our solutions ensure the highest standards of cleanliness and quality for both fuel and electric vehicle components, enhancing their performance and reliability.